Custom pipe racks are a key component in industrial construction, providing essential organization and support for pipes, cables, and utilities across various sectors. Industries such as oil and gas, pharmaceuticals, and manufacturing rely on these structures to efficiently manage complex piping systems while maintaining safety and durability.

Custom-designed pipe racks optimize space, streamline project execution, and enhance accessibility for maintenance, reducing downtime and operational risks. By accommodating specific project requirements, these racks ensure structural integrity, compliance with industry standards, and improved workflow efficiency, making them an indispensable element in modern industrial infrastructure.

What Are the Benefits of Using Custom Pipe Racks in Industrial

Construction?

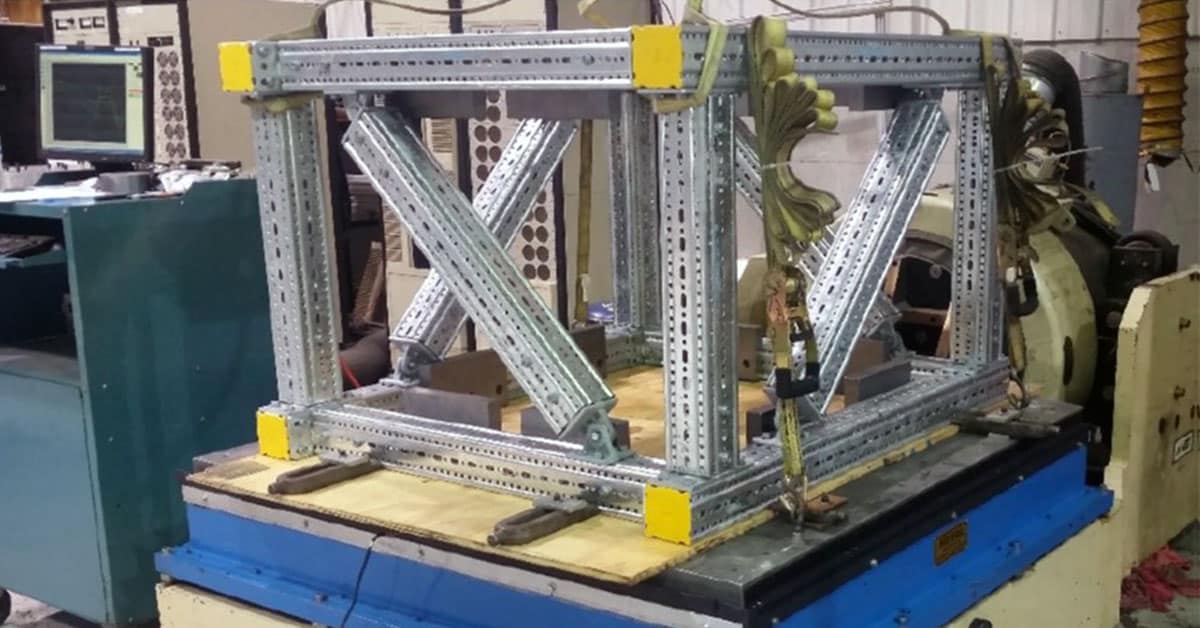

Custom pipe racks offer significant advantages by adapting to complex layouts and evolving project requirements, ensuring seamless integration into industrial environments. Their use of high-quality materials enhances durability and reliability, providing long-term structural stability even in demanding conditions. The modular nature of these designs simplifies installation, minimizes errors, and accelerates construction timelines, reducing overall project costs.

Additionally, their accessible configurations facilitate easy maintenance, allowing for quick inspections and repairs without disrupting operations. By combining flexibility, strength, and efficiency, custom pipe racks play a vital role in optimizing industrial infrastructure and ensuring sustained performance.

What Factors Should Be Considered When Designing Custom Pipe Racks?

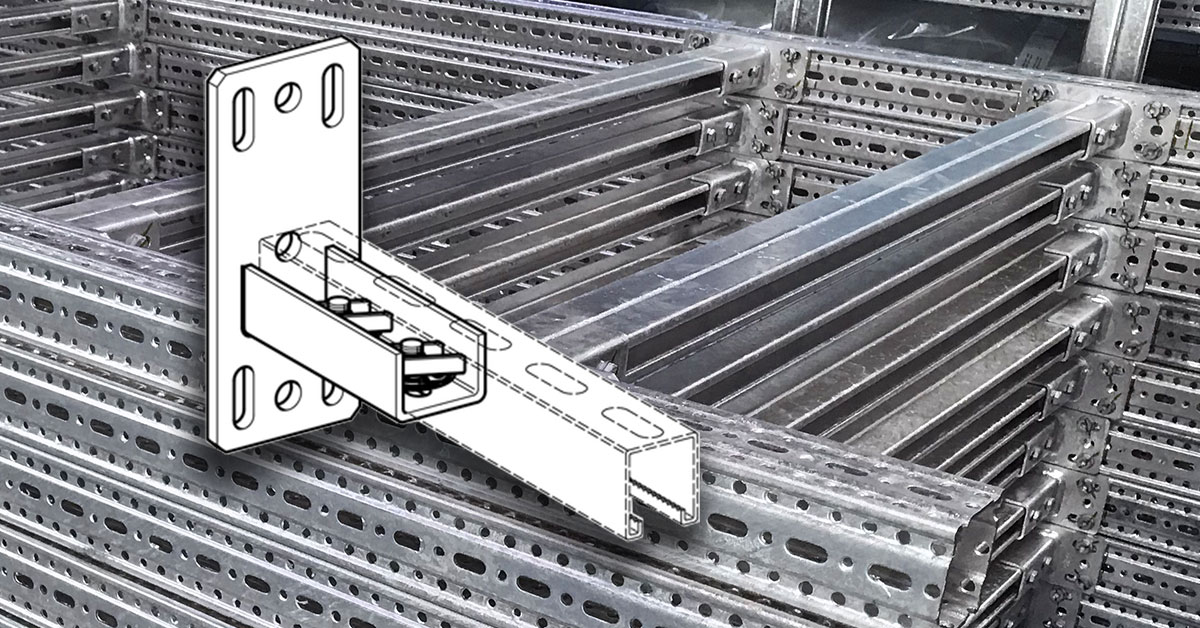

- Load Capacity is a major factor in the design and material selection of custom pipe racks, ensuring stability and reliability under varying operational demands. Engineers must account for the weight of pipes, fluids, and additional equipment.

- Material Choice is another factor to consider. Engineers commonly choose materials such as galvanized steel or coated alloys to withstand mechanical stress and environmental conditions.

- Exposure to extreme temperatures, corrosion, and other harsh factors further influences design choices, requiring protective coatings or specialized materials for longevity.

- Space optimization is equally vital, particularly in complex industrial layouts where efficient rack configurations maximize utility without compromising accessibility.

- Modularity is essential for accommodating future expansions or modifications, allowing for adaptability in evolving projects.

- Regulatory Compliance is a fundamental aspect of the design process, ensuring that all structures meet industry safety and quality standards to protect workers and maintain operational integrity.

Custom Pipe Racks are Essential Solutions for Industrial Construction

Custom pipe racks serve critical roles across various industries, ensuring efficient organization and support for essential systems. In manufacturing, these racks streamline material transport, facilitating the smooth flow of raw materials and finished products in high-production facilities.

For example, in a petrochemical plant, custom pipe racks might help manage high-pressure pipelines while withstanding extreme temperatures, while in an automotive factory, they optimize space for efficient assembly line operations. Their adaptability and durability make them indispensable in demanding industrial environments, enhancing safety, efficiency, and long-term reliability.

OIL & GAS: In the oil and gas sector, they provide structural stability for extensive pipeline networks, safely managing the transport of hazardous materials in refineries and drilling sites.

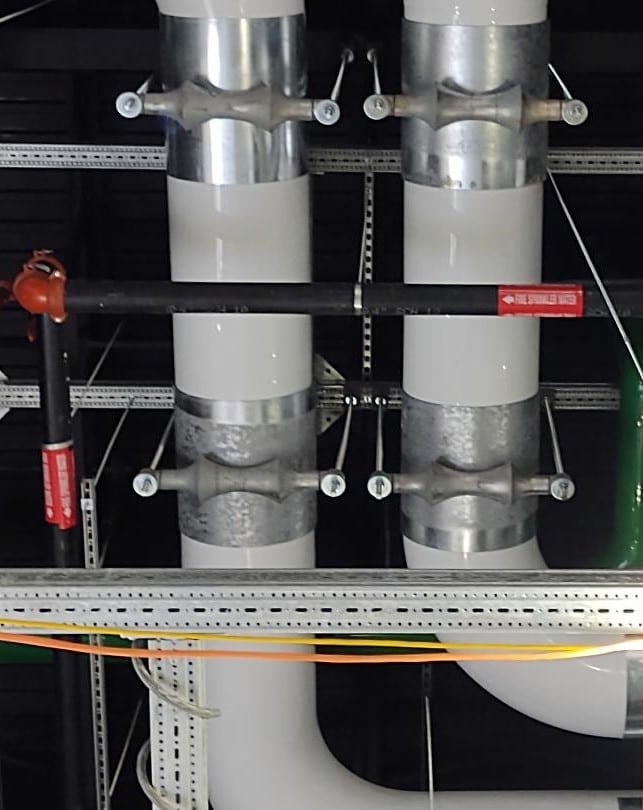

PHARMACEUTICALS: The pharmaceutical industry relies on precision-engineered pipe racks to maintain sterile environments, supporting utility lines for cleanroom operations and ensuring regulatory compliance.

MANUFACTURING: Companies that focus on mass production benefit from custom pipe rack systems in numerous ways. Once installed, pipe racks reduce trip hazards, improve access for maintenance, and ensure smooth production flow.

ENERGY & POWER: In power plants and renewable energy facilities, pipe racks support critical piping for steam, cooling water, and fuel distribution, enhancing system reliability and minimizing downtime.

COMMERCIAL & INSTITUTIONAL: Large-scale buildings like hospitals, universities, and data centers use pipe racks to manage HVAC, plumbing, and fire suppression systems, optimizing space while ensuring maintenance accessibility.

These tailored solutions enhance efficiency, durability, and overall project success, ensuring that facilities operate smoothly and safely. For industries requiring precision and reliability, custom pipe racks are a game-changer.

Why Choose MMS Custom Pipe Racks?

Modular Mechanical Systems has a proven track record of delivering custom pipe rack solutions tailored to the unique demands of industrial construction projects. Our expertise lies in designing racks that accommodate specific project requirements, ensuring optimal support for piping, cables, and utilities while adhering to strict industry safety and quality standards.

At MMS we utilize high-quality, modular materials that provide durability and long-term reliability, even in harsh industrial environments. Our modular approach allows for easy installation, scalability, and future modifications, making our solutions adaptable to evolving project needs. By combining engineering precision with compliance and innovation, MMS continues to be a trusted partner in optimizing industrial infrastructure.

Have a project and in need of guidance?

Let our experts assist you in making the right decision!