Because Installation Should Be Easy

It’s our mission to make your job easier, so we supply our Silka support systems to you in kit form for much faster field installation.

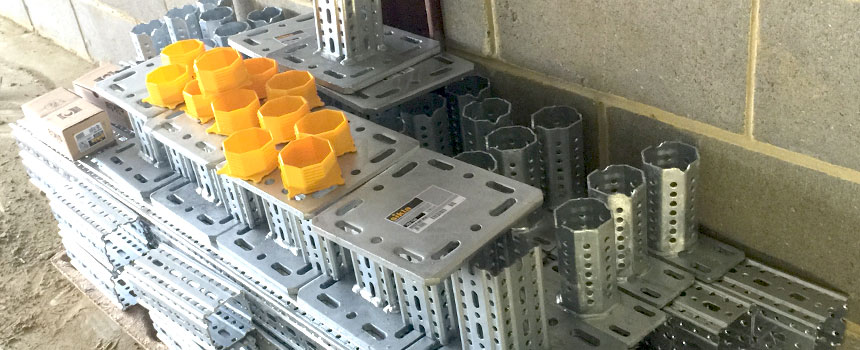

Parts, pieces, and subassemblies are flat packed on sturdy pallets, clearly labeled to correspond to your shop drawings, shrink wrapped, and shipped directly to your prefabrication warehouse or job site.

All you need to assemble your framework is a 20 volt drill. The FLS Form Screw hardware is used to make all connections, greatly simplifying the assembly process.

No hot works, such as riveting, welding, flame cutting or other fire or spark-producing operations are necessary, making assembly much safer. There is also no needs for grinding, hole-drilling, cutting, or painting.

The Benefits are Obvious

- Ease of Installation

- No Hot Works: Welding, Riveting, Flame Cutting, etc.

- No Hole-Drilling, Cutting, Grinding or Painting

- Universal Connection Hardware Simplifies Assembly

- Clearly Labeled Components and Subassemblies

- Vibration Proof Connections Ensure Safe Travel

US Dept of Defense MIL-STD 810g standards

If you’re planning on assembling off-site then transporting fully assembled to your job site, there’s no need to worry about shipping. We offer a vibration resistant system that conforms to US Dept of Defense MIL-STD 810g standards.

During testing, all axes were exposed to vibration for 2 hours. The test module passed with no visible damage or deterioration of any of the connections within it. Two hours per axis, represents a 2000 mile journey by US Highway.