Modular Pipe Rack Systems for PIPE, CONDUIT and DUCT are revolutionizing the construction industry and making us rethink how we go about the installation process.

With improvements in design software, the ability to generate an itemized list, down to the last component, of exactly what you need to install on your site, or at your prefabrication facility, is now possible.

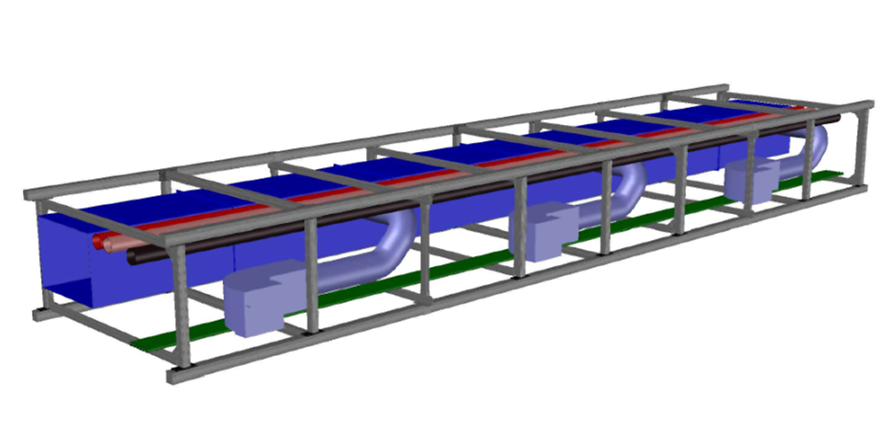

Modular Pipe Racks can be modeled and fully engineered with Sikla framo components. All components are then securely packaged, labeled and shipped to your off-site prefabrication facility or job site.

Completing assembly of your modular Multi Trade Rack off-site, in the controlled environment of a prefabrication warehouse, allows for assembly line work to be performed by each trade, increasing speed, quality, and safety. Building your modular rack off-site also cuts down on job site labor.

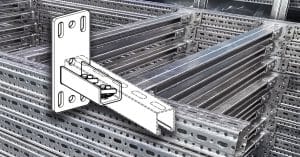

The need for on-site fabrication or modification is greatly reduced, and can be accomplished simply with the use of a 20 volt drill, leading to a significant time savings. The built-in efficiencies of this modular pipe rack system allow you to more easily complete rigorous construction schedules on time.

Key Benefits of Multi-Trade Pipe Racks

- Adjustable Off-Site and In-Field

- Can Be Prefabricated Off-Site

- Increased Time Savings

- Fewer Parts and Pieces

- Same Hardware Used In All Connections

- Assembles With a 20v Drill

- No Welding, Drilling, Cutting, or Grinding

- Faster Assembly

- Better Quality Control

- Decreased Waste

- Improved Safety

We Design It, You Assemble It

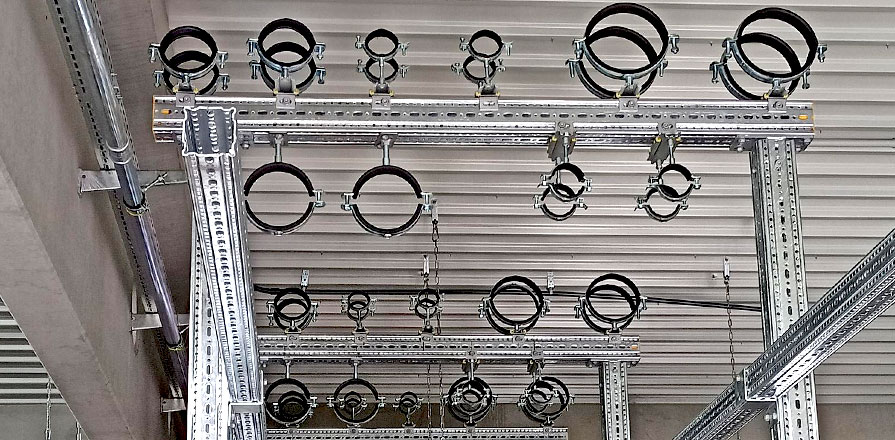

Our multi-discipline pipe support racks are constructed of modular support members that assemble as easily as metal framing, but perform as well as structural steel. SiFramo components have all the strength of structural steel but none of the hassle of fabrication. Components are modular, adjustable and require absolutely no welding, grinding, hole-drilling, cutting, or painting.

We ship your fully labeled frame components to your prefabrication warehouse (or job site) for easy assembly and then your tradesmen complete installation of all the mechanical pipe, electrical conduit, and any other trade components. Your modular, prefabricated multi-trade pipe racks are then ready to be shipped to your job site and installed in a fraction of the time traditional construction takes.

Modular Pipe Rack Applications:

- Corridor / Riser Frames and Modules

- Data Center Modules

- Medical Support Grids

- Duct Riser Steelwork

CASE STUDIES

VİEW ALL MIL-STD-810g Achieved with Thread Forming Screws

May 04 2022

MIL-STD-810g Achieved with Thread Forming Screws

May 04 2022