In today’s rapidly changing world, the construction industry faces increasing pressure to reduce its environmental footprint and embrace more sustainable practices. As global awareness of climate change and resource depletion continues to rise, builders and developers are seeking innovative ways to minimize waste, lower energy consumption, and create structures that are both efficient and environmentally responsible.

One emerging solution at the forefront of this movement is the use of modular supports—versatile systems designed to streamline construction while promoting sustainability. By offering a smarter, more adaptable alternative to traditional methods, modular supports are helping reshape the future of construction, making it greener, cleaner, and more efficient from the ground up.

What Are Modular Supports, and How Are They Used in Construction?

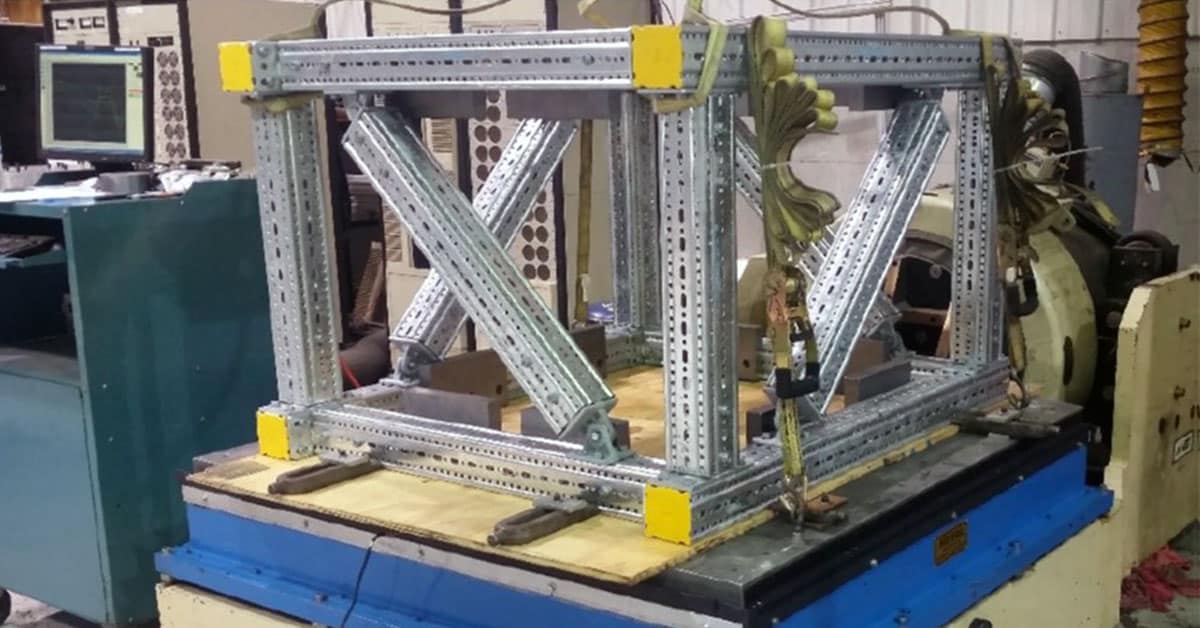

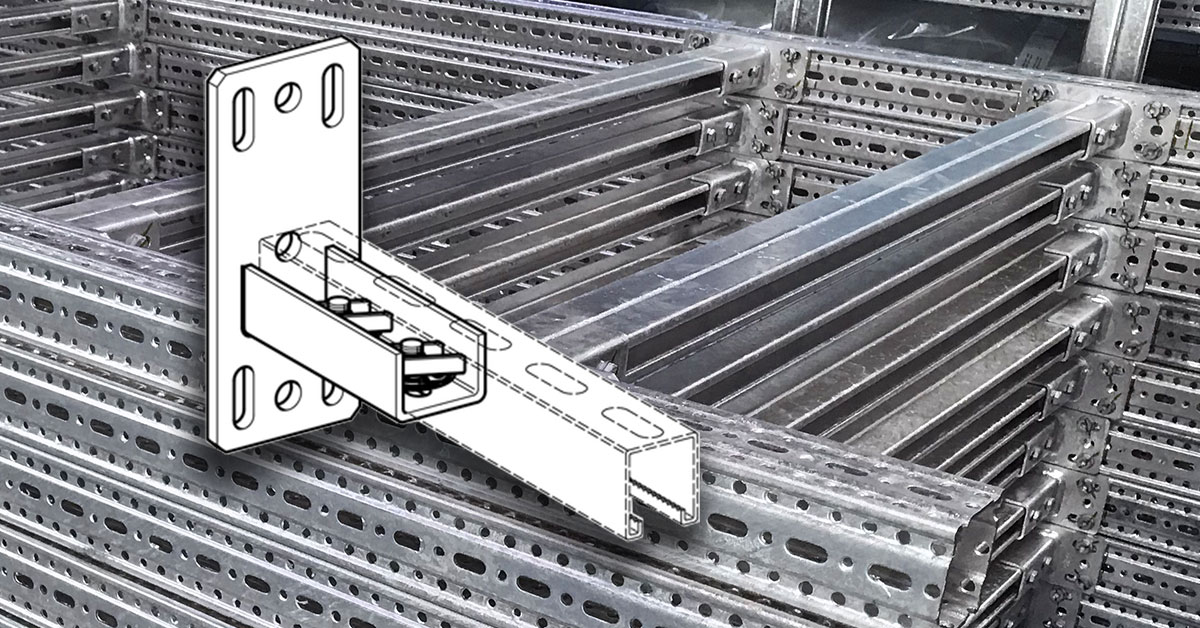

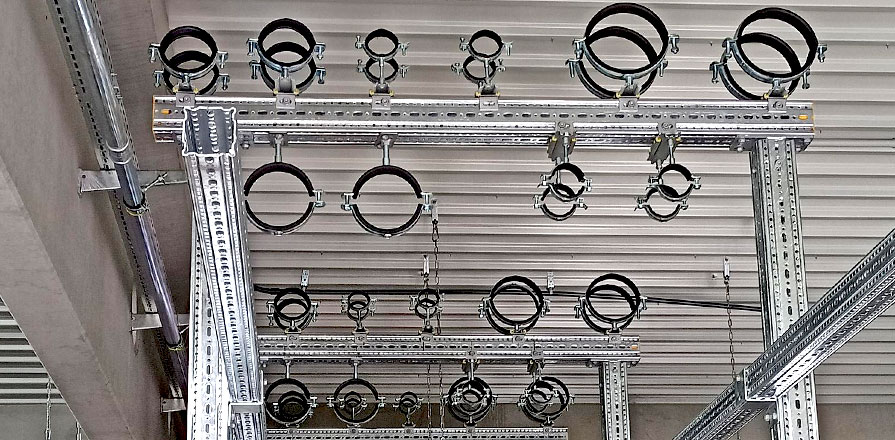

Modular supports are prefabricated, pre-engineered systems designed to provide structural and mechanical support in construction projects. These components are manufactured off-site under controlled conditions and delivered ready for installation, eliminating the need for complex fabrication at the job site. Modular supports are commonly used to hold piping, ductwork, electrical systems, and other structural elements in place, ensuring proper alignment and stability throughout a building’s framework.

By arriving pre-measured and pre-assembled, these systems help streamline the construction process, reduce the likelihood of human error during installation, and significantly cut down on the time and labor typically required for on-site adjustments. Their standardized design ensures consistent quality and allows for faster, more accurate project execution.

How Can Modular Supports Contribute to Sustainable Construction?

Modular supports play a key role in reducing the environmental footprint of construction by promoting precision and efficiency throughout the building process. Because these systems are prefabricated in controlled factory environments, material usage is carefully calculated, which drastically cuts down on off-cuts and scrap that would typically be generated on-site. This streamlined production often leads to waste reductions of up to 90% compared to traditional construction methods.

Additionally, the need for fewer on-site adjustments shortens project timelines, which means less energy is consumed running heavy equipment and fewer deliveries are needed, reducing emissions tied to transportation. By minimizing errors and rework, modular supports help ensure that raw materials are used only as intended, directly supporting the industry’s push toward leaner, more sustainable construction practices.

Case Studies: Real-World Applications of Modular Supports in Sustainable Construction

- One example of modular supports driving sustainability can be seen in the construction of a major data center in Virginia, where the use of prefabricated support systems cut material waste by nearly 85% compared to traditional methods, thanks to precise factory measurements and minimized on-site cutting.

- In another project, a hospital expansion in Seattle incorporated modular supports for its mechanical and plumbing systems, which significantly reduced on-site energy consumption — fewer welding machines, power tools, and heavy equipment were needed, cutting the site’s energy usage by an estimated 30% during the installation phase.

- Finally, in a high-rise residential development in Chicago, the adoption of modular supports helped the project shave nearly two months off the original schedule, reducing the length of construction-related emissions from machinery and transport while allowing the building to begin energy-efficient operations sooner.

Each of these cases highlights how modular supports not only simplify construction but also deliver tangible environmental benefits across various stages of a project.

How Modular Supports Minimize On-Site Modifications and Improve Project Flexibility

Beyond their role in streamlining construction, modular supports offer a high level of operational flexibility that contributes to long-term efficiency and sustainability. Because these systems are pre-engineered with adaptability in mind, they can be customized to meet the exact specifications of a project, reducing the likelihood of costly and time-consuming on-site alterations. This level of precision ensures that fewer resources are consumed during installation and future modifications are easier to implement without major overhauls.

Modular supports are also designed to accommodate future upgrades or expansions, allowing components to be added, repositioned, or replaced without the need for significant demolition or reconstruction. This adaptability not only extends the useful life of a building’s infrastructure but also makes it easier for facilities to evolve alongside new technologies and changing requirements, further supporting resource-efficient, future-ready construction.

Why Modular Supports Are Essential for Sustainable Construction Practices

Modular supports represent a crucial step forward in modern construction, offering a smart balance between efficiency and sustainability. By enabling faster project timelines, minimizing material waste, and reducing on-site energy consumption, these systems address some of the industry’s most pressing environmental challenges right from the start.

Their built-in adaptability allows structures to evolve over time, making future upgrades and reconfigurations easier and more resource-efficient, which not only extends the lifespan of a building but also helps meet ever-tightening green standards. As construction continues to shift toward scalable, future-proof solutions, modular supports stand out as an essential tool for building smarter, cleaner, and more responsibly in a world that increasingly demands sustainable progress.

Why Choose Modular Mechanical Supports (MMS)?

Modular Mechanical Supports stands out as a trusted leader in modular support solutions, combining years of industry experience with a strong commitment to quality and sustainability. Our company’s expertise in designing and delivering tailored, prefabricated systems ensures that every project—whether large or small—benefits from precision-engineered supports that reduce waste, save time, and simplify future upgrades.

We at MMS understand that no two construction projects are the same, which is why we work closely with clients to align their modular solutions with specific sustainability goals, helping reduce environmental impact while enhancing long-term performance. As the construction industry moves toward greener and more efficient practices, MMS is uniquely positioned to help companies achieve their sustainability goals while maintaining the highest standards of quality and adaptability.

Have a project and in need of guidance?

Let our experts assist you in making the right decision!