What is Skid Mounted Equipment?

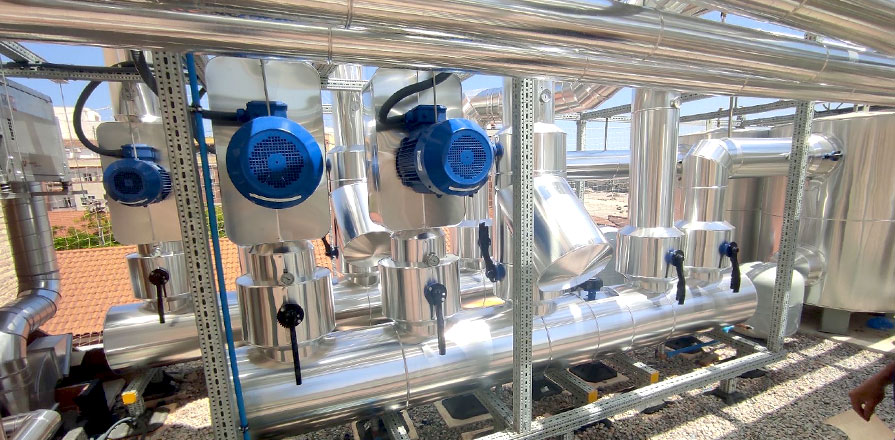

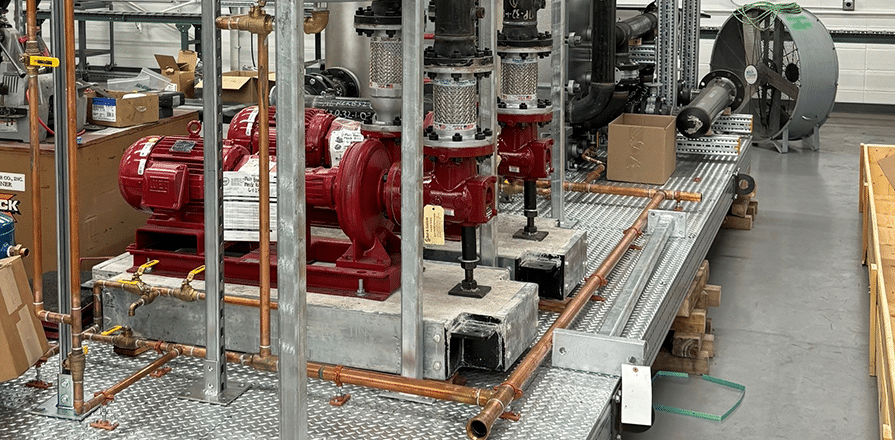

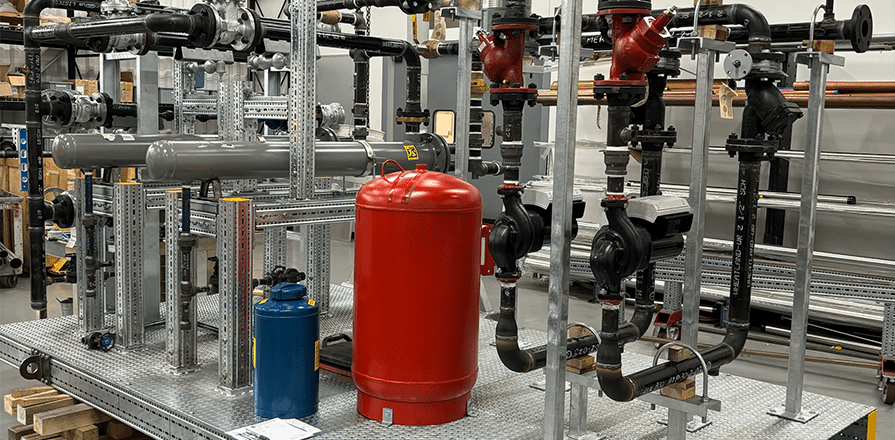

In terms of industrial process equipment, an equipment skid is a metal frame or platform, built for heavy equipment and systems to be mounted to. It is modular in design, meaning it can be fully built off-site in a controlled environment, transported to the job when needed, and put into place. Equipment skids protect equipment and systems during transportation and support them after they have been installed on the job site.

What Are The Main Benefits of Process Equipment Skids?

- Modularity: easily incorporates with other modular systems already in place

- Mobility: completed systems are transported from the build site to the job site

- Efficiency: off-site building streamlines the construction and installation process

- Protection & Support: protects during transport and supports when installed

What Types of Process Equipment are Equipment Skids Made For?

- Pumps

- Piping

- Valves

- Tanks / Vessels

- Filters

- Coolers

- Heat Exchangers

- Pulsation Dampeners, and more!

What Makes the Sikla Equipment Skid Better?

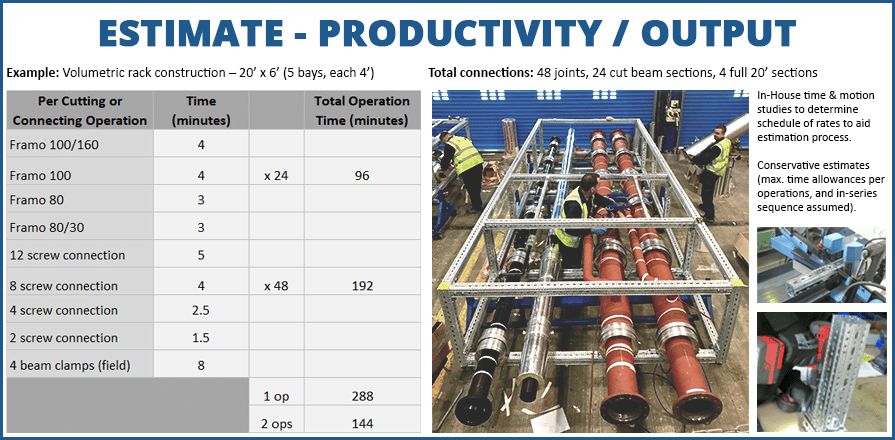

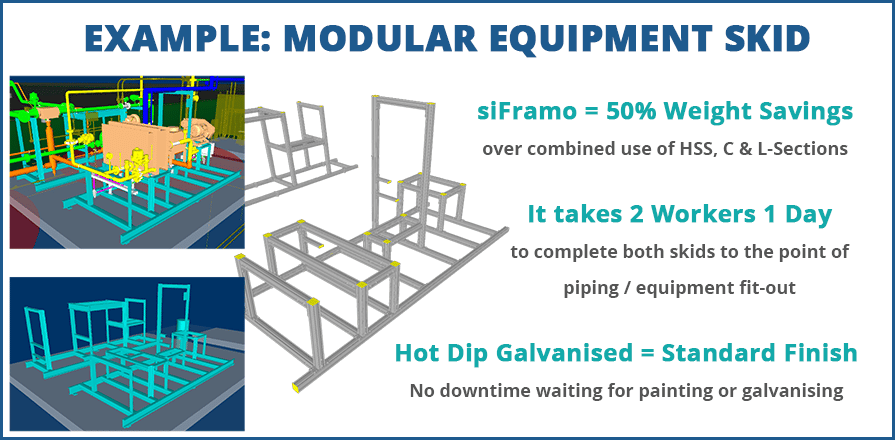

Improve Productivity by Reducing Fabrication Time!

Modular equipment skid frameworks have revolutionized the way prefabricated construction and industrial products are put together. We take it one step further, providing a replacement for structural steel and fabrication, using Sikla.

Sikla siFramo makes a much better building material than traditional materials, such i-beam, angle, or steel channel, because it is a fully modular and adjustable steelwork solution. It provides structural support, without the hassle of fabrication, virtually eliminating the need for welding, grinding, hole-drilling, cutting, or painting.

Our team will take your equipment skid design and value-engineer it, using siFramo, to create a fully modular support solution for you. Your skid can be fully assembled off-site, using only a 20 volt drill. Any field adjustments can also be made with the same ease, using the same tool.

What are Some Applications for Process Equipment?

- Petrochemical

- Water Treatment Plants

- Steam Power Generation

- Saltwater Disposal

- Food & Beverage Production

- Mining

- Pharmaceutical

- Industrial

- Mechanical

- Chemical

- Hot Skids, and more!

free productivity report!

Let us provide you with a free productivity / output report specific to your job

request a quote