Sikla siFramo Structural Framing

Modular Structural Steel

Sikla Framo (siFramo) is a fully modular and adjustable system of beams and fittings that offers structural support without any of the hassle of fabricated steel. It’s also the backbone of our Modular Mechanical Support Systems!

Building with siFramo components drastically improves installation times since there is no need for welding, hole-drilling, cutting, grinding, or painting, and all components attach with a single piece of hardware. The advantages are clear.

Key Benefits

- Fully Modular System with the Strength of Fabricated Steel

- Installs Much Faster than Fabricated Steel

- All Connections Made with One-Size-Fits-All Thread Forming Screw

- Hot Dip Galvanized for Superior Corrosion Resistance

- Integrates with Other Metal Framing Systems, including Unistrut

Sikla Modular Steel vs Fabricated Steel Supports

Sikla siFramo System Components

SiFramo is a comprehensive – yet simple – system which consists of a variety of structural beams, fittings, base plates and a single – yet highly effective – piece of attachment hardware, used to secure them all together.

Beam Sections

Beam sections are 20 feet in length with two standard widths: siFramo 80 has a 3-1/8″ width, while siFramo 100 has a 3-15/16″ width. Both are available in several heights. All four sides of the structural member allow for mechanical connection, making siFramo a very versatile choice.

Foot Plates / Base Plates

A variety of foot plate options are available for either steel or concrete connections. Welding plates are also available for implementations where siFramo is being incorporated into existing fabricated structural steel structures, or clamping is not an option.

Beam Connectors / Fittings

Fittings consist of a variety of joint brackets, end supports, couplers, channel adapters, beam connectors and more. SiFramo is a robust system, with a complete line of attachment fittings, for an endless array of configuration possibilities.

Attachment Hardware

All beam to fitting connections are made with a single piece of hardware, which installs easily with a standard impact driver. The FLS Self Forming Screw comes in only one size, eliminating stock problems and simplifying the installation process.

The FLS creates its own thread inside the wall of the siFramo pilot hole. During the screw-driving operation, the base steel is re-shaped and hardened to form an air-tight seal between the threads of the screw and the surrounding steel, making it exceptionally resistant to vibrational loosening and increasing fastening strength.

Strongback Adjustable Pipe Supports

Modular Supports as Strong as Structural Steel

Strongback adjustable pipe supports and hangers are completely modular pipe support systems designed for hanging pipe. Sikla siFramo structural framing members support your pipes with the strength of structural steel, but without any of the hassle of fabrication.

Our strongback adjustable pipe supports can be installed up to five times faster than traditional, fabricated steel supports because they require absolutely no welding, grinding, hole-drilling, cutting, or painting!

Strongback Adjustable Pipe Supports Key Benefits

- Engineered Strength

- 4-Sided Connection Points

- Less Weight to Lift into Place

- Adjustable Horizontal Connections

- 7/16″ x 1″ Slots Secure Both Rod and Hardware

- Multiple Pipe Shoe Options

Strong, Versatile Pipe Hangers

Strongback mechanical, electrical and plumbing pipe hangers and supports utilize heavy-duty fabricated steel clevis hangers and modular structural beams, supported by threaded rod. Versatile, four-sided structural beams allow for a variety of pipe support brackets and pipe support configurations.

Strongback XL Pipe Support: SB-SF80 utilizes a 3″ x 3″ siFramo 80 beam section.

Strongback XXL Pipe Support: SB-SF100 utilizes a 4″ x 4″ siFramo 100 beam section.

Click To: Download the SB-SF80 & SB-SF100 product specifications

A variety of pipe shoe assemblies are available to suit your specific application needs. Pipe shoes attach with simple, one-size-fits-all thread forming screws that are removable and reusable.

Strongback Construction Applications

- Water Supply Lines

- Gas Lines

- Mechanical Piping

- Electrical Conduit

- Condensate Pipe

- Refrigeration Lines

- and More

Silverback Strongbacks Pipe Support

Strong & Cost Effective Square Tube Strongbacks

Silverback Strongbacks are completely modular adjustable pipe supports systems designed for hanging MEP pipe. Square tubes support your pipes with the strength of structural steel, but without any of the hassle of fabrication.

Our Silverback Strongback adjustable pipe supports can be installed up to five times faster than traditional, fabricated steel supports because they require absolutely no welding, grinding, hole-drilling, cutting, or painting field adjustments necessary!

A wide variety of pipe supports and hangers can be attached directly to the square tubing supports. Even more versatility can be achieved by mounting strut channel to our Silverback Strongback Pipe Supports to increase the variety of pipe and conduit clamps that can be affixed to include strut mounted pipe clamp options.

Silverback Strongbacks Key Benefits

- Weight Loading up to 10,000 lbs

- Utilizes Standard All Thread from 1/2″ to 1″

- Assembled by a Visually Impaired Person

- All Hardware is Electro-Galvanized

- Tubing Sections are Pre-Galvanized or Hot Dip Galvanized

- Bracketry is Hot Dip Galvanized

- Project Takeoff & Quote Available

Strong, Versatile Strongback Pipe Hangers

Silverback Strongback pipe supports for mechanical, electrical and plumbing applications utilize heavy-duty fabricated steel brackets, standard hardware and square tubes, supported by threaded rod. Versatile, four-sided square tubing allows for a variety of pipe support brackets and pipe support configurations.

12 Gauge Supports (Available in 4′, 6′, & 8′ Lengths)

*also available in 10′ Lengths with midspan drop support

Silverback Strongback Pipe Support: SB-150 utilizes 1-1/2″ Square Tube Sections

Silverback Strongback Pipe Support: SB-175 utilizes 1-3/4″ Square Tube Sections

Silverback Strongback Pipe Support: SB-200 utilizes 2″ Square Tube Sections

Silverback Strongback Pipe Support: SB-225 utilizes 2-1/4″ Square Tube Sections

Silverback Strongback Pipe Support: SB-250 utilizes 2-1/2″ Square Tube Sections

10 Guage Pipe Supports (Available in 4′, 6′, 8′, & 10′ Lengths)

Silverback Strongback Pipe Support: SB-219 utilizes 2-3/16″ Square Tube Sections

Silverback Strongback Pipe Support: SB-250 utilizes 2-1/2″ Square Tube Sections

* All above supports (with the exception of the SB-150 and the SB-219) can be further strengthened by the addition of interior telescoping tubing supports that slide directly inside the main support tubes.

* Addition of midspan drop support improves deflection

* Contact us for seismic designs

Click To: Download the SB-200 Product Specifications (still need to update link w/ new submittal)

Strongback Construction Applications

- Water Supply Lines

- Gas Lines

- Mechanical Piping

- Electrical Conduit

- Condensate Pipe

- Refrigeration Lines

- and More

| Part Number | Load Capacity (Lbs) | Description | Gauge | Length |

|---|---|---|---|---|

| SB-150121-4 | 1912 | (2) 1.5″ Square Tubes | 12 | 4 Feet |

| SB-150121-6 | 1276 | (2) 1.5″ Square Tubes | 12 | 6 Feet |

| SB-150121-8 | 956 | (2) 1.5″ Square Tubes | 12 | 8 Feet |

| SB-175121-4 | 2922 | (2) 1.75″ Square Tubes | 12 | 4 Feet |

| SB-175121-6 | 1940 | (2) 1.75″ Square Tubes | 12 | 6 Feet |

| SB-175121-8 | 1460 | (2) 1.75″ Square Tubes | 12 | 8 Feet |

| SB-175122-4 | 4834 | (2) 1.75″ Square Tubes Telescoped with (2) 1.5″ Interior Tubes | 12 | 4 Feet |

| SB-175122-6 | 3216 | (2) 1.75″ Square Tubes Telescoped with (2) 1.5″ Interior Tubes | 12 | 6 Feet |

| SB-175122-8 | 2416 | (2) 1.75″ Square Tubes Telescoped with (2) 1.5″ Interior Tubes | 12 | 8 Feet |

| SB-200121-4 | 4116 | (2) 2″ Square Tubes | 12 | 4 Feet |

| SB-200121-6 | 2736 | (2) 2″ Square Tubes | 12 | 6 Feet |

| SB-200121-8 | 2058 | (2) 2″ Square Tubes | 12 | 8 Feet |

| SB-200122-4 | 7038 | (2) 2″ Square Tubes Telescoped with (2) 1.75″ Interior Tubes | 12 | 4 Feet |

| SB-200122-6 | 4676 | (2) 2″ Square Tubes Telescoped with (2) 1.75″ Interior Tubes | 12 | 6 Feet |

| SB-200122-8 | 3518 | (2) 2″ Square Tubes Telescoped with (2) 1.75″ Interior Tubes | 12 | 8 Feet |

| SB-225121-4 | 5524 | (2) 2.25″ Square Tubes | 12 | 4 Feet |

| SB-225121-6 | 3666 | (2) 2.25″ Square Tubes | 12 | 6 Feet |

| SB-225121-8 | 2766 | (2) 2.25″ Square Tubes | 12 | 8 Feet |

| SB-225122-4 | 9640 | (2) 2.25″ Square Tubes Telescoped with (2) 2″ Interior Tubes | 12 | 4 Feet |

| SB-225122-6 | 6402 | (2) 2.25″ Square Tubes Telescoped with (2) 2″ Interior Tubes | 12 | 6 Feet |

| SB-225122-8 | 4824 | (2) 2.25″ Square Tubes Telescoped with (2) 2″ Interior Tubes | 12 | 8 Feet |

| SB-250121-4 | 7092 | (2) 2.5″ Square Tubes | 12 | 4 Feet |

| SB-250121-6 | 4728 | (2) 2.5″ Square Tubes | 12 | 6 Feet |

| SB-250121-8 | 3558 | (2) 2.5″ Square Tubes | 12 | 8 Feet |

| SB-250122-4 | 10,000+ | (2) 2.5″ Square Tubes Telescoped with (2) 2.25″ Interior Tubes | 12 | 4 Feet |

| SB-250122-6 | 8394 | (2) 2.5″ Square Tubes Telescoped with (2) 2.25″ Interior Tubes | 12 | 6 Feet |

| SB-250122-8 | 6324 | (2) 2.5″ Square Tubes Telescoped with (2) 2.25″ Interior Tubes | 12 | 8 Feet |

| SB-219101-4 | 6436 | (2) 2.19″ Square Tubes | 10 | 4 Feet |

| SB-219101-6 | 4308 | (2) 2.19″ Square Tubes | 10 | 6 Feet |

| SB-219101-8 | 3232 | (2) 2.19″ Square Tubes | 10 | 8 Feet |

| SB-219101-10 | 2576 | (2) 2.19″ Square Tubes | 10 | 10 Feet |

| SB-250101-4 | 8566 | (2) 2.5″ Square Tubes | 10 | 4 Feet |

| SB-250101-6 | 5700 | (2) 2.5″ Square Tubes | 10 | 6 Feet |

| SB-250101-8 | 4282 | (2) 2.5″ Square Tubes | 10 | 8 Feet |

| SB-250101-10 | 3416 | (2) 2.5″ Square Tubes | 10 | 10 Feet |

| SB-250102-4 | 10,000+ | (2) 2.5″ Square Tubes Telescoped with (2) 2.19″ Interior Tubes | 10 | 4 Feet |

| SB-250102-6 | 10,000 | (2) 2.5″ Square Tubes Telescoped with (2) 2.19″ Interior Tubes | 10 | 6 Feet |

| SB-250102-8 | 7514 | (2) 2.5″ Square Tubes Telescoped with (2) 2.19″ Interior Tubes | 10 | 8 Feet |

| SB-250102-10 | 5992 | (2) 2.5″ Square Tubes Telescoped with (2) 2.19″ Interior Tubes | 10 | 10 Feet |

*** Users should consult with the manufacturer for their specific project prior to installation ***

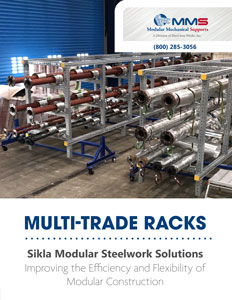

Multi-Trade Pipe Racks

Modular Pipe Rack Systems for PIPE, CONDUIT and DUCT are revolutionizing the construction industry and making us rethink how we go about the installation process.

With improvements in design software, the ability to generate an itemized list, down to the last component, of exactly what you need to install on your site, or at your prefabrication facility, is now possible.

Modular Pipe Racks can be modeled and fully engineered with Sikla framo components. All components are then securely packaged, labeled and shipped to your off-site prefabrication facility or job site.

Completing assembly of your modular Multi Trade Rack off-site, in the controlled environment of a prefabrication warehouse, allows for assembly line work to be performed by each trade, increasing speed, quality, and safety. Building your modular rack off-site also cuts down on job site labor.

The need for on-site fabrication or modification is greatly reduced, and can be accomplished simply with the use of a 20 volt drill, leading to a significant time savings. The built-in efficiencies of this modular pipe rack system allow you to more easily complete rigorous construction schedules on time.

Key Benefits of Multi-Trade Pipe Racks

- Adjustable Off-Site and In-Field

- Can Be Prefabricated Off-Site

- Increased Time Savings

- Fewer Parts and Pieces

- Same Hardware Used In All Connections

- Assembles With a 20v Drill

- No Welding, Drilling, Cutting, or Grinding

- Faster Assembly

- Better Quality Control

- Decreased Waste

- Improved Safety

We Design It, You Assemble It

Our multi-discipline pipe support racks are constructed of modular support members that assemble as easily as metal framing, but perform as well as structural steel. SiFramo components have all the strength of structural steel but none of the hassle of fabrication. Components are modular, adjustable and require absolutely no welding, grinding, hole-drilling, cutting, or painting.

We ship your fully labeled frame components to your prefabrication warehouse (or job site) for easy assembly and then your tradesmen complete installation of all the mechanical pipe, electrical conduit, and any other trade components. Your modular, prefabricated multi-trade pipe racks are then ready to be shipped to your job site and installed in a fraction of the time traditional construction takes.

Modular Pipe Rack Applications:

- Corridor / Riser Frames and Modules

- Data Center Modules

- Medical Support Grids

- Duct Riser Steelwork

MEP Corridor Modular Racks

Modular Racks and other prefabricated modular MEP systems are revolutionizing construction efficiency! In the rapidly evolving construction industry, efficiency and precision are paramount. MEP corridor modular racks are at the forefront of this transformation, offering a streamlined solution for mechanical, electrical, and plumbing (MEP) systems. As a leading provider of prefabricated modular MEP systems, we understand the critical role these modular racks play in modern construction projects.

Modular Racks in MEP Construction

Modular racks, specifically designed for MEP applications, bring numerous advantages to construction projects. By integrating mechanical, electrical, and plumbing components into a single, cohesive unit, these racks simplify the installation process and significantly reduce on-site labor. This modular approach ensures that each component is precisely fitted, enhancing the overall quality and reliability of the MEP systems. Prefabricated MEP racks are manufactured in a controlled environment, which minimizes the risk of errors and delays commonly encountered in traditional construction methods.

Ground Mounted Corridor Racks

Ground mounted corridor racks are a specific type of modular rack designed to support MEP systems at ground level. These racks are particularly beneficial in projects where ceiling-mounted systems are not feasible, due to structural or other limitations.

Ground mounted corridor racks offer exceptional stability and support for heavy MEP components. Their design allows for efficient use of space in corridors and other accessible areas, optimizing the layout and functionality of the building. These racks can accommodate a wide range of MEP elements, including HVAC ducts, electrical conduits, and plumbing pipes, providing a comprehensive solution for integrating all essential systems.

The Benefits of Prefabricated MEP Racks

One of the most significant benefits of using prefabricated MEP racks is the time savings they offer. With modular racks, much of the assembly is completed off-site, allowing for faster installation on-site. This not only accelerates the construction timeline but also reduces the disruption to other trades working on the project.

Understanding MEP in Construction

MEP stands for mechanical, electrical, and plumbing, which are critical components in any building project. MEP systems are responsible for the essential services that make buildings habitable and functional, such as heating, cooling, lighting, and water supply. In MEP construction, precision and coordination are crucial, as these systems are interdependent and must work seamlessly together. Prefabricated MEP racks offer a solution to these challenges by providing a pre-assembled, tested, and optimized system that ensures compatibility and efficiency.

Ground mounted corridor racks represent a significant advancement in the integration and management of MEP systems. Their versatility, ease of access, and robust design make them an ideal choice for modern construction projects, ensuring that all mechanical, electrical, and plumbing components are securely and efficiently installed. By embracing these innovative solutions, construction projects can achieve higher standards of quality and efficiency, ultimately leading to better outcomes and greater satisfaction for all stakeholders involved.

Adjustable MEP Support Frames

A Modular Alternative to Fabricated Steel Supports

Adjustable MEP Support Frames use a system of modular structural steel beams and components, called Sikla, to replace fabricated steel in the construction of secondary steel frame structures. The simplicity engineered into Sikla’s siFramo product line allows for safer, cleaner, more efficient installation.

Key Benefits

- Easy Installation

- Lighter Than Structural Steel

- 4-Sided Connection Points

- Multiple Pipe Support Options

- Same Hardware Used In All Connections

- Assembles With a 20v Drill

- Field Adjustable

- No Welding, Hole-Drilling, Cutting, or Grinding

Durable Systems That Install Easily

MEP Support Frames have built in flexibility due to the way connections between beams and fittings are made. There is zero need for welding or complicated hardware setups. Frames utilize a removable, reusable, one-size-fits-all thread form screw to secure all components to beams, making them fully adjustable systems that are simple to install and can adapt to future changes.

Our team will work closely with you on your next project, creating a support solution for your mechanical systems. We provide Building Information Modeling (BIM), design, and engineering support throughout your project.

Systems are supplied in kit form, which could include preassembly of certain components, then components and subassemblies are flat-packed and tagged to correspond with shop drawings. Our systems are packed this way for maximum efficiency, ease of assembly, and the fastest possible field installation.

Applications

- H-stands

- T-posts

- Equipment Bases

- Floor to Roof Corridor Framing

- Roof Support Frames

Equipment Skid Systems

What is Skid Mounted Equipment?

In terms of industrial process equipment, an equipment skid is a metal frame or platform, built for heavy equipment and systems to be mounted to. It is modular in design, meaning it can be fully built off-site in a controlled environment, transported to the job when needed, and put into place. Equipment skids protect equipment and systems during transportation and support them after they have been installed on the job site.

What Are The Main Benefits of Process Equipment Skids?

- Modularity: easily incorporates with other modular systems already in place

- Mobility: completed systems are transported from the build site to the job site

- Efficiency: off-site building streamlines the construction and installation process

- Protection & Support: protects during transport and supports when installed

What Types of Process Equipment are Equipment Skids Made For?

- Pumps

- Piping

- Valves

- Tanks / Vessels

- Filters

- Coolers

- Heat Exchangers

- Pulsation Dampeners, and more!

What Makes the Sikla Equipment Skid Better?

Improve Productivity by Reducing Fabrication Time!

Modular equipment skid frameworks have revolutionized the way prefabricated construction and industrial products are put together. We take it one step further, providing a replacement for structural steel and fabrication, using Sikla.

Sikla siFramo makes a much better building material than traditional materials, such i-beam, angle, or steel channel, because it is a fully modular and adjustable steelwork solution. It provides structural support, without the hassle of fabrication, virtually eliminating the need for welding, grinding, hole-drilling, cutting, or painting.

Our team will take your equipment skid design and value-engineer it, using siFramo, to create a fully modular support solution for you. Your skid can be fully assembled off-site, using only a 20 volt drill. Any field adjustments can also be made with the same ease, using the same tool.

What are Some Applications for Process Equipment?

- Petrochemical

- Water Treatment Plants

- Steam Power Generation

- Saltwater Disposal

- Food & Beverage Production

- Mining

- Pharmaceutical

- Industrial

- Mechanical

- Chemical

- Hot Skids, and more!

Pump Skid Systems

Sikla modular Pump Skids enhance the efficiency of fluid handling systems. In the realm of fluid handling and processing, the importance of efficiency, reliability, and ease of installation cannot be overstated. Sikla modular pump skids embody these qualities, providing a robust solution for various industrial applications. As a leading provider of prefabricated modular skid systems, we recognize the transformative impact that high-quality pump skids can have on your operations.

What is a Pump Skid?

A pump skid is specialized type of equipment skid designed to be a self-contained, pre-assembled unit for housing pump equipment, motors, piping, valves, and control systems. All this fluid handling equipment gets mounted on a custom designed frame, known as a pump skid. These systems handle fluid transfer, boosting, and circulation tasks in a wide range of industries, from water treatment to oil and gas. The modular nature of Sikla pump skids allows for easy integration into existing processes, offering a versatile and efficient solution for fluid management.

Advantages of Skid Systems

Skid systems, including pump skids, offer numerous benefits over traditional, on-site assembly methods. Prefabrication in a controlled environment ensures that all components are precisely aligned and thoroughly tested before delivery. This reduces the risk of errors and ensures a higher level of quality and reliability. Additionally, skid systems are designed for quick installation, minimizing downtime and disruption to ongoing operations. The modular design allows for easy scalability and future expansion, providing a flexible solution that can grow with your needs.

Sikla Pump Skid Design

The design of Sikla pump skids prioritizes efficiency, durability, and ease of maintenance. Each skid is meticulously engineered to meet specific application requirements, ensuring optimal performance. Components are selected based on their compatibility and performance characteristics, resulting in a cohesive system that operates seamlessly. The compact and robust design of these skids makes them ideal for space-constrained environments, while their modularity allows for customization and adaptability to various operational demands.

What is Skid Mounted Equipment?

Skid mounted equipment refers to machinery and systems that are mounted on a skid, providing a stable and portable platform. This setup facilitates transport, installation, and maintenance, as the entire unit can be moved as a single piece. For pump skids, this means that the pumps, motors, and ancillary components are all securely mounted on a skid, ensuring structural integrity and simplifying logistics. Skid mounted equipment is particularly advantageous in industries where mobility and rapid deployment are crucial.

Why Choose Sikla Modular Pump Skids?

Sikla modular pump skids are designed to deliver superior performance and reliability in demanding industrial environments. By opting for our prefabricated skid systems, you benefit from reduced installation time, lower labor costs, and enhanced system integrity. Our commitment to quality and innovation ensures that every pump skid we deliver meets the highest standards of excellence. Whether you need a solution for fluid transfer, pressure boosting, or chemical processing, Sikla pump skids offer the efficiency and dependability you require.

Tank Skid / Vessel Skid Systems

Sikla modular tank skids and vessel skids are optimizing storage and transport solutions! In industries where storage and transport of liquids and gases are critical, Sikla modular tank and vessel skids offer an unparalleled solution. As a leading provider of prefabricated modular skid systems, we specialize in delivering high-quality, reliable, and efficient skids designed to meet the diverse needs of our clients. Our tank skids are engineered to provide superior performance, ease of installation, and enhanced operational efficiency.

Understanding Tank Skids and Vessel Skids

A tank skid is a specialized type of equipment skid that is a prefabricated modular frame custom designed to house your tanks or vessels. These systems are designed to facilitate the storage, transport, and handling of various liquids and gases. Vessel skids can range from fuel tank skids to water storage tanks and chemical processing vessels. The modular nature of Sikla tank skids ensures that they are adaptable to a wide range of applications, providing a flexible and scalable solution for your storage needs.

Benefits of Skid Systems in Tank and Vessel Applications

Skid systems, including those used for tanks and vessels, offer numerous advantages over traditional, on-site assembly methods. Prefabrication in a controlled environment guarantees precise alignment and thorough testing of all components before delivery. This minimizes the risk of installation errors and ensures higher quality and reliability. Additionally, skid systems are designed for quick and easy installation, reducing downtime and labor costs. The modular design allows for easy scalability and future expansion, making Sikla tank skids an excellent choice for evolving operational requirements.

Sikla Tank Skid Design

Sikla modular tank skids are meticulously designed to ensure optimal performance, durability, and ease of maintenance. Each skid is engineered to meet specific application requirements, incorporating features such as corrosion-resistant materials, secure mounting systems, and efficient piping configurations. The compact and robust design of these skids makes them suitable for space-constrained environments, while their modularity allows for customization and adaptability to various operational demands. Our skidding system ensures that tanks and vessels are securely mounted, providing stability and safety during transport and operation.

Applications of Tank Skids

Tank skids are used in a variety of industries, including oil and gas, chemical processing, water treatment, and fuel storage. Fuel tank skids, for example, are designed to safely store and transport fuels, ensuring compliance with industry standards and regulations. Skids tanks used in water treatment plants facilitate the storage and processing of large volumes of water, while chemical processing tanks are designed to handle corrosive and hazardous substances. The versatility of Sikla tank skids makes them an ideal solution for any application requiring secure and efficient storage and transport of liquids and gases.

Why Choose Sikla Modular Tank and Vessel Skids?

Sikla modular tank and vessel skids offer superior performance and reliability in demanding industrial environments. By choosing our prefabricated skid systems, you benefit from reduced installation time, lower labor costs, and enhanced system integrity. Our commitment to quality and innovation ensures that every tank skid we deliver meets the highest standards of excellence. Whether you need a solution for fuel storage, water treatment, or chemical processing, Sikla tank skids provide the efficiency and dependability you require.

Sikla modular tank and vessel skids represent a significant advancement in storage and transport technology. Their prefabricated design, combined with the advantages of skid systems, provides a reliable and efficient solution for various industrial applications. As experts in modular skid systems, we are dedicated to delivering products that enhance the performance and efficiency of your operations, ensuring that you achieve the best possible outcomes with minimal hassle.

Skid House Frame

At Modular Mechanical Supports, we are proud to be a trusted Sikla solution specialist and distributor, dedicated to delivering cutting-edge solutions for modular construction. The Sikla skid house frame exemplifies our commitment to providing robust, versatile, and efficient foundations for a wide range of housed skid applications, particularly in industrial MEP (mechanical, electrical, and plumbing) equipment support. Whether you require housed skid frames for industrial equipment, temporary housing, or specialized shelters, our prefabricated modular skid systems offer a dependable and customizable solution tailored to meet your specific needs.

Key Benefits of Sikla Skid House Frames

- Durability: Built with high-quality materials, our skid house frames are designed to withstand harsh environmental conditions, ensuring long-term reliability and stability.

- Flexibility: The modular nature of our housed skid frames allows for easy customization to meet specific project requirements, making them suitable for a variety of applications.

- Efficiency: Prefabrication in a controlled environment guarantees precise construction and quick on-site installation, reducing overall project timelines and costs.

- Transportability: The robust design of our housed skids ensures they can be easily transported and relocated, providing flexibility for dynamic project needs.

- Safety: Our skid house frames adhere to strict safety standards, ensuring that your housed skid systems are secure and compliant with industry regulations.

Partnering with Modular Mechanical Supports

When you partner with Modular Mechanical Supports for your skid house frame needs, you can expect unparalleled expertise and dedication to quality. Our team of professionals works closely with you to understand your specific requirements and deliver tailored solutions that meet your project goals. We offer comprehensive support from the initial design phase through to installation, ensuring a seamless and efficient process. Our commitment to innovation and customer satisfaction means you can trust us to provide the best housed skid frames for your industrial MEP equipment support needs.

Sikla skid house frames represent the pinnacle of modular construction, providing a versatile and reliable solution for a wide range of applications. By choosing our housed skid systems, you are investing in quality, efficiency, and adaptability, ensuring the success of your projects, particularly in the realm of industrial MEP equipment support.

Applications for Housed Skid Frames

- HVAC Systems: Providing durable and secure housing for heating, ventilation, and air conditioning units, ensuring optimal performance and protection.

- Pumping Stations: Robust support for various types of pumps, including centrifugal, diaphragm, and peristaltic pumps, used in water treatment, chemical processing, and other industrial applications.

- Electrical Panels and Switchgear: Secure enclosures for electrical distribution and control equipment, protecting sensitive components from environmental hazards and ensuring reliable operation.

- Water Treatment Systems: Housing for filtration units, reverse osmosis systems, and other water treatment equipment, ensuring efficient operation and easy maintenance.

- Generator Sets: Providing stable and secure support for backup power generators, ensuring reliable power supply during outages.

- Process Equipment: Customizable frames for various process equipment such as heat exchangers, boilers, and reactors, ensuring stability and ease of access for maintenance.